COMMON BEARING FAILURES

Understanding why a bearing has failed is one of the best ways to prevent the same failure from happening again. We list the most common bearing failures to help you decide what has happened with your bearing.

INSTRUCTIONS: The gallery below looks at each failure type with a slideshow of images. Use the red arrow to reveal a general description for each slideshow, and use the grey left/right arrows to swipe through the slideshow. Note, the captions will change with each new image.

Send us your photos of failed or damaged bearings through this website for analysis. Just click through to our contact page, where you will find the facility to attach and upload images alongside a message, for our team to examine. We'll get back to you with our initial thoughts and advise on how best to investigate the damage or failure.

UPLOAD YOUR PHOTO

COMMON BEARING FAILURES

Understanding why a bearing has failed is one of the best ways to prevent the same failure from happening again. We list the most common bearing failures to help you decide what has happened with your bearing.

INSTRUCTIONS: The gallery below looks at each failure type with a slideshow of images. Use the red arrow to reveal a general description for each slideshow, and use the grey left/right arrows to swipe through the slideshow. Note, the captions will change with each new image.

Send us your photos of failed or damaged bearings through this website for analysis. Just click through to our contact page, where you will find the facility to attach and upload images alongside a message, for our team to examine. We'll get back to you with our initial thoughts and advise on how best to investigate the damage or failure.

UPLOAD YOUR PHOTO

Contact Us

We will get back to you as soon as possible.

Please try again later.

-

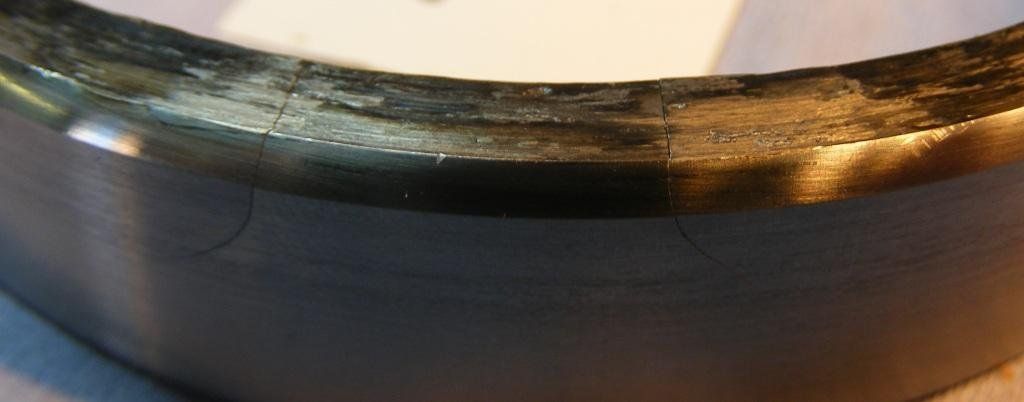

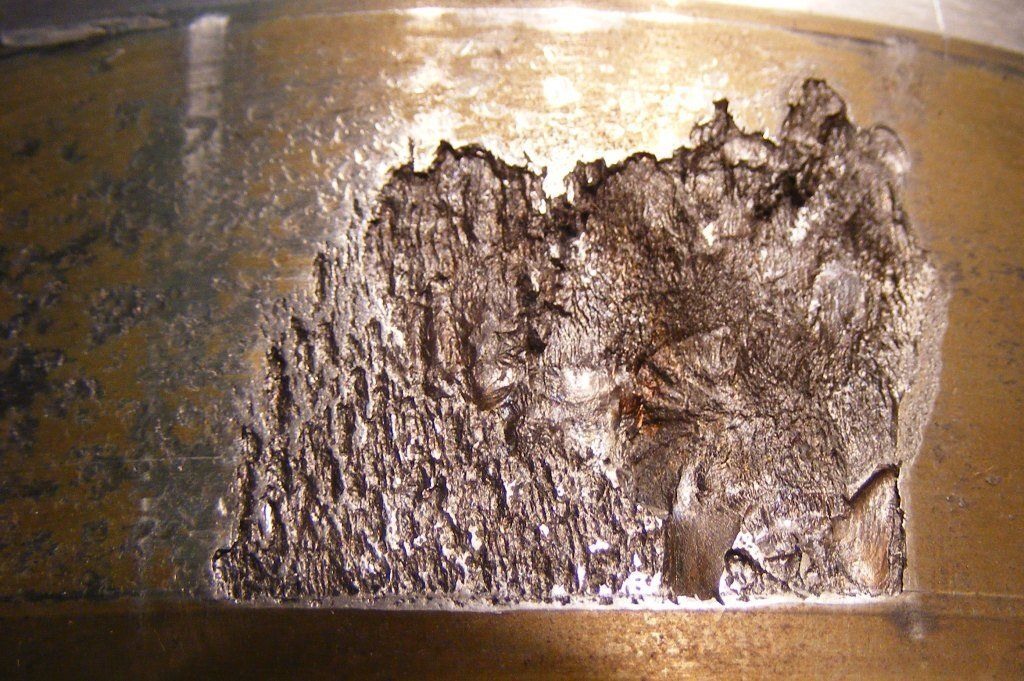

BEARING FLAKING OR WEARING FATIGUE

Flaking due to rolling fatigue occurs when small pieces of bearing material are lifted and broken off the smooth surface of the raceway or the rolling elements. This flaking causes regions with a rough and coarse texture.

Slide title

Fatigue damage in a loaded zone of a

tapered roller bearing inner ring

Button

Slide title

Flaking on the edge of a tapered roller inner ring

Button

Slide title

A spherical roller damaged as a result of flaking and fatigue

Button

Slide title

Flaking on a ball bearing outer ring raceway

Button

Slide title

Flaking on a ball bearing outer ring raceway

Button

Slide title

Fatigue at both sides of a crack in a Tapered roller cone

Button

-

BEARING PEELING

Dull or cloudy spots appear on the raceway surface along with light wearing. Tiny microscopic cracks are generated downward from these cloudy spots to a depth of 5-10 μm. Small particles of material then peel from the surface with areas of minor flaking starting to occur.

Slide title

A spherical roller raceway with surface material peeled away

Button

-

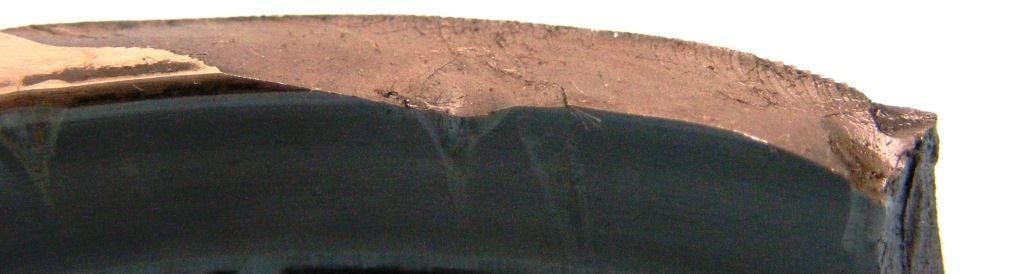

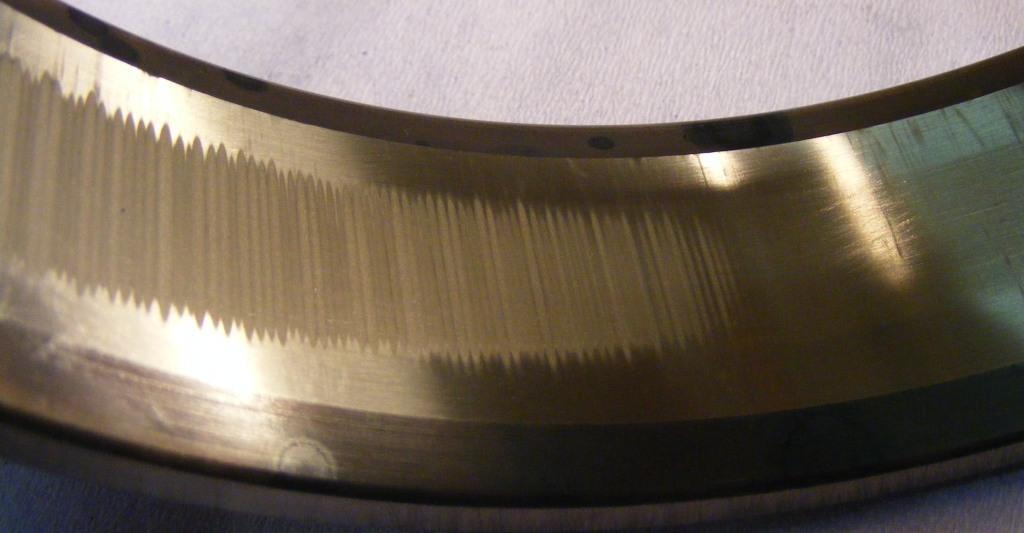

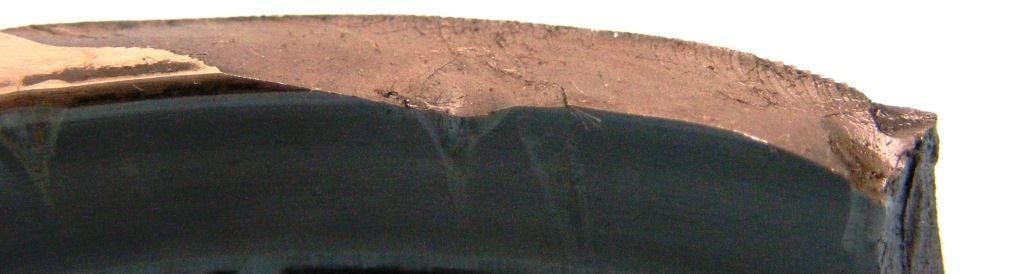

BEARING SCORING

Scoring is surface damage due to accumulated small seizures caused by sliding under improper lubrication or severe operating conditions. Linear damage appears circumferentially on the raceway and roller surfaces. Cycloidal shaped damage on the roller ends and scoring on the rib surface contacting roller ends also occur.

Slide title

A spherical roller central divider scored as a result of an ineffective lubricant film thickness being present

Button

Slide title

A prominent scoring mark caused by a lack of radial clearance during service rotation. Swirl shaped scuffing and scoring on the ends of a failed taper roller bearing

Button

-

SMEARING OF THE BEARING SURFACE

Smearing is surface damage which occurs from a collection of small seizures between bearing components caused by oil film rupture and/or sliding. Surface roughening occurs along with melting.

Slide title

A smeared end of a tapered rolled as a result of excessive sliding contact against the roller retaining rib

Button

Slide title

Smearing on the inner races of a duplex tapered roller

Button

-

FRACTURE OF THE BEARING

Fracture refers to small or large metallic pieces which were broken off due to excessive load or shock load acting locally on a rolling element, rib or section of a raceway ring.

Slide title

Fracture of a spherical roller bearing outer ring as a result of a high thrust impact load causing cracks

Button

Slide title

Cracking in the outer ring of an angular contact bearing

Button

-

CRACKS IN THE RACEWAY RING AND ROLLING ELEMENTS

Cracks in the raceway ring and rolling elements. Continued use under this condition leads to larger cracks or fractures

Slide title

Outer ring crack caused by a heavy impact through the rolling elements

Button

Slide title

Inner ring crack caused by excessive hoop stress

Button

-

BEARING CAGE DAMAGE, DEFORMATION, FRACTURE AND WEAR

Cage damage includes: Cage deformation, Fracture and Wear Fracture of cage pillars.

Slide title

Tapered roller cage with worn side pillars caused by the bearing having run in a reduced lubricant condition

Button

Slide title

Wear in a brass cage pocket due to low lubrication

Button

Slide title

An angular contact bearing cage deformed due to rubbing contact with other assembly parts

Button

Slide title

Wear of pocket surface. Brass cage pillar wear caused by lack of lubrication

Button

-

PITTING OF THE BEARING ON THE ROLLING ELEMENT OR RACEWAY

Pitting has a dull lustre and appears on the rolling element surface or raceway surface.

Slide title

Light pitting as seen on the two sides of a spherical roller inner ring

Button

Slide title

Pitting around the circumference of a cylindrical roller inner ring

Button

-

DENTING AND "PEAR SKINNING" OF THE BEARING

When Flaking due to rolling fatigue occurs, small pieces of bearing material become trapped in the lubricant and are crushed on the raceways by the rolling elements. This effect can also occur if the lubricant becomes contaminated.

Slide title

Dented cross roller thrust bearing raceway caused by dirt ingress following a strip down and re assembly

Button

Slide title

Raceway damaged by contaminant in the lubricant

Button

Slide title

Pear skinning caused by metal debris from a fatigue failure being pressed onto the remainder of the contact surface

Button

Slide title

Fatigue occurring on a ball bearing inner ring due to stresses induced around an impact dent

Button

-

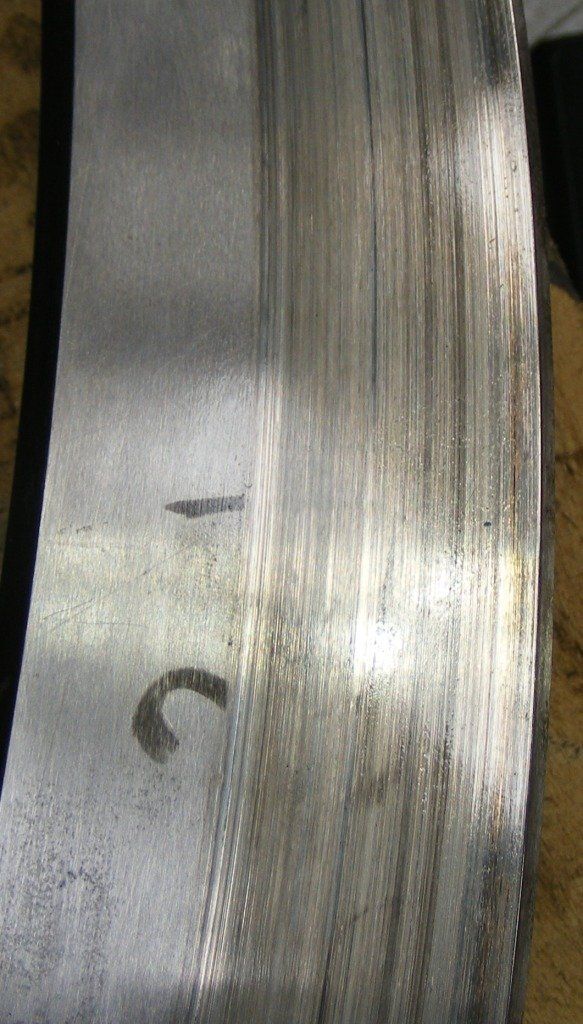

WEAR OF BEARINGS

Wear is surface deterioration due to sliding friction at the surface of the raceway, rolling elements, roller end faces, rib face, cage pockets, etc.

Slide title

Rotation and surface wear in the bore of a tapered roller bearing inner ring. The possible cause being that the shaft was damaged previously allowing movement to occur

Button

Slide title

Close up of a Tapered Roller nose with heavy burrs and rotational scuffing due to maladjustment of the bearing on the shaft

Button

-

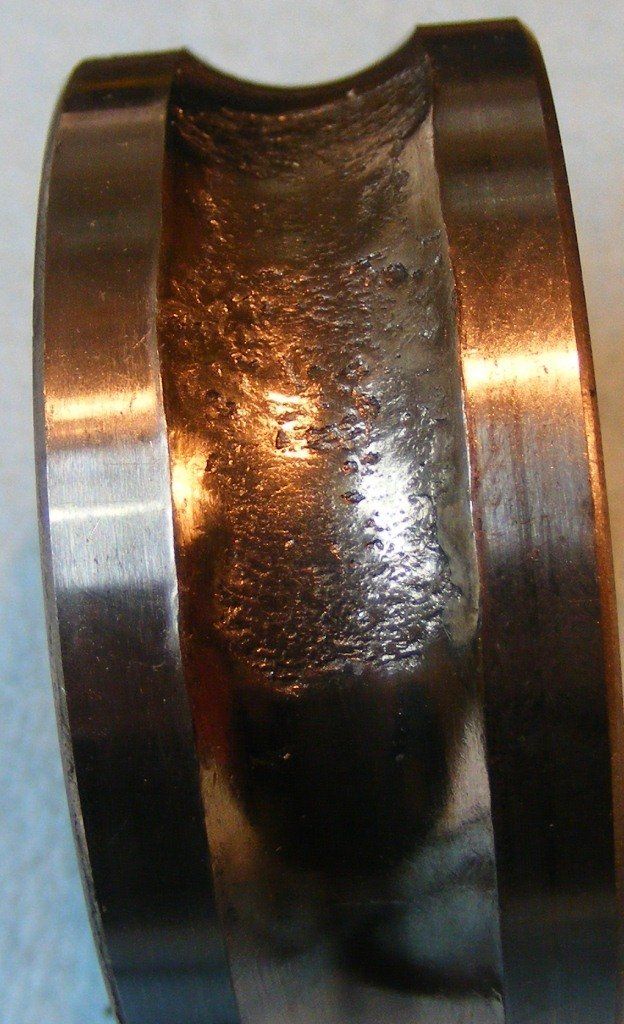

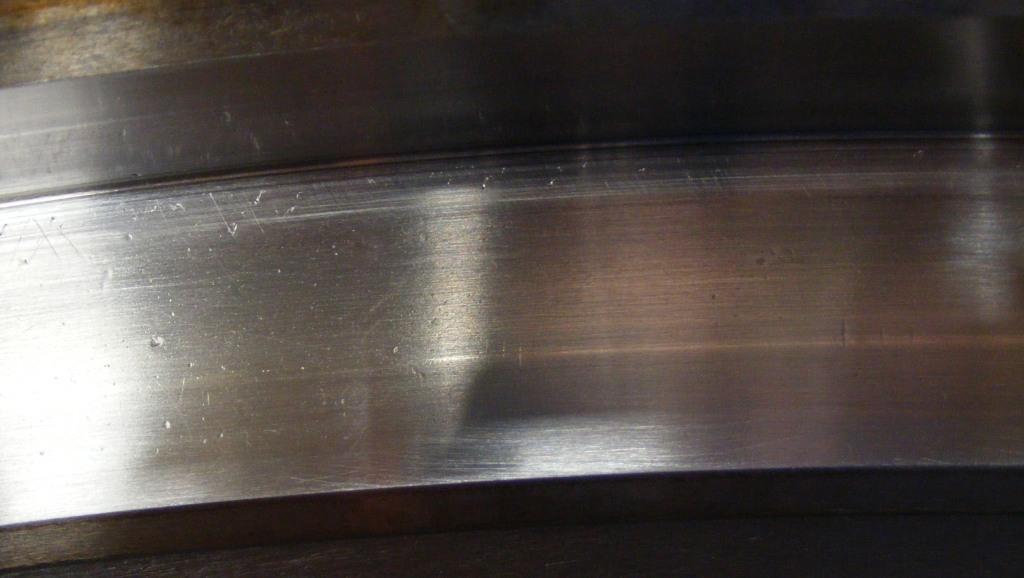

FRETTING OF BEARINGS

Wear occurs due to repeated sliding between the two surfaces. Fretting occurs at fitting surface between raceway rings and the shaft or housing. Fretting corrosion is another term used to describe the reddish brown or black wear patterns often seen on old shafts and worn housings.

Slide title

Top surface of a thrust bearing showing sliding wear marks to one side of the ring as a result of unintended movement during service

Button

Slide title

Fitting marks and fretting corrosion caused by the bearing vibrating on the shaft

Button

Slide title

Fretting Corrosion and Fitting marks on the outside diameter of a spherical roller outside diameter

Button

-

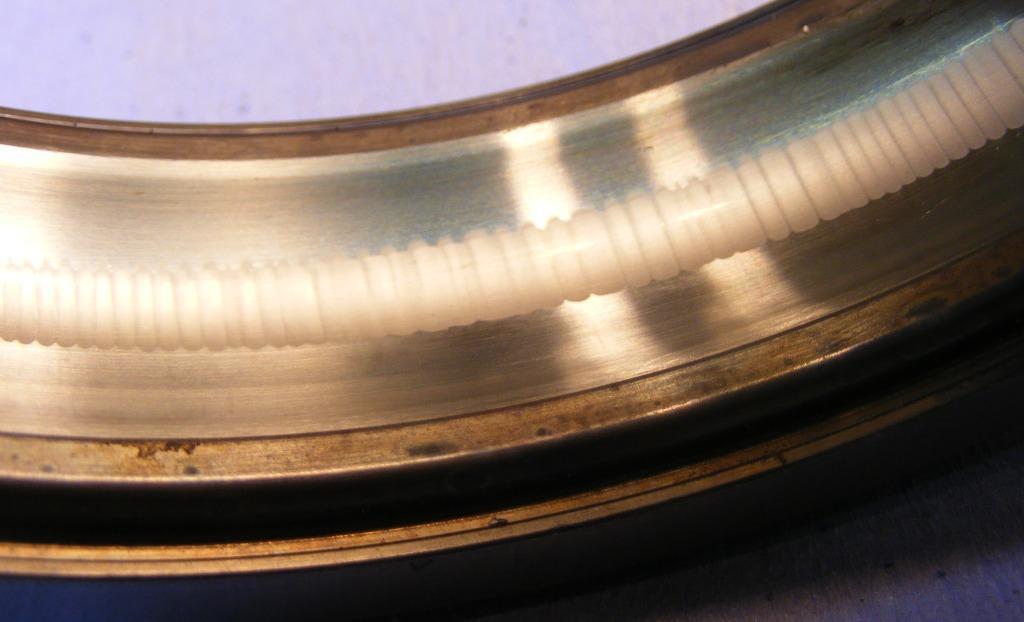

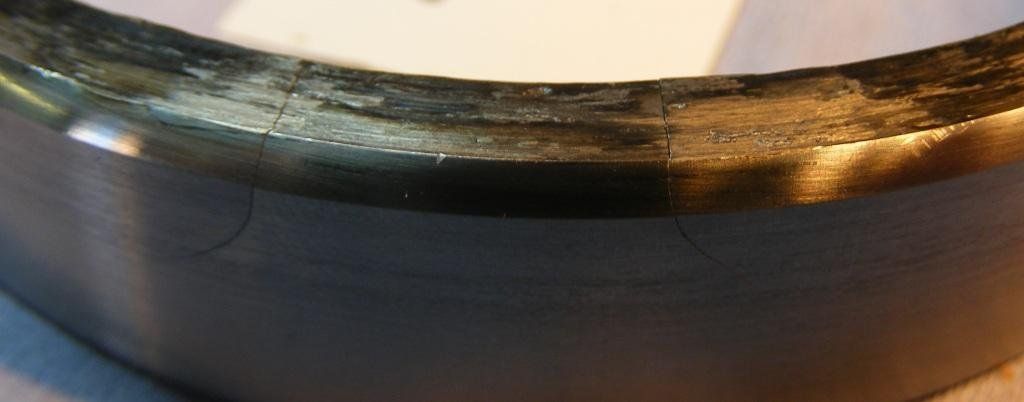

FALSE BRINELLING

Among the different types of fretting, false brinelling is the occurrence of hollow spots that resemble brinell dents and are due to wear caused by vibration and swaying at the contact points between the rolling elements and raceway.

Slide title

False brinelling caused during transportation of the stationary component

Button

Slide title

False brinelling and scratches likely to have been caused during transportation of inappropriately packed bearings

Button

-

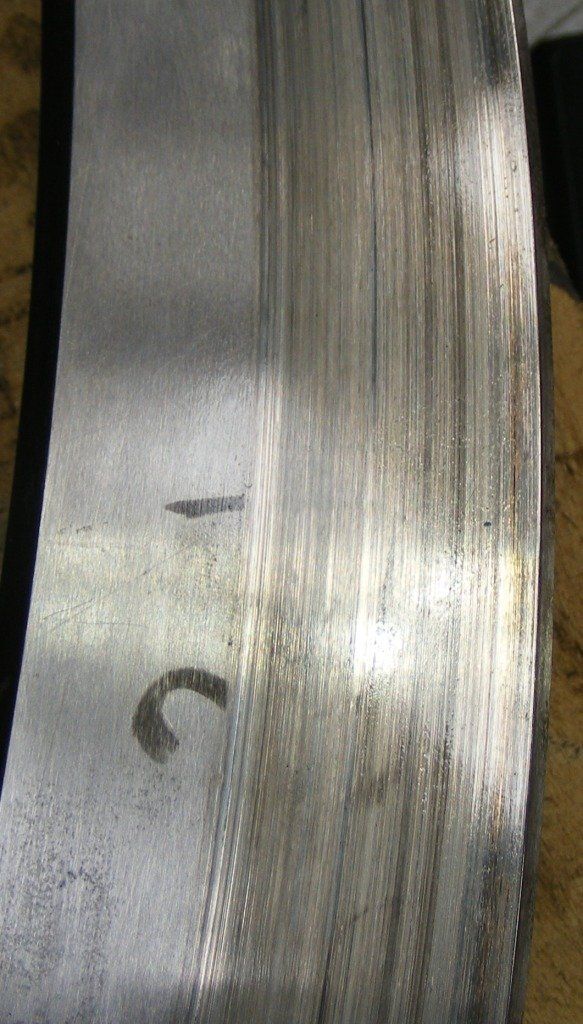

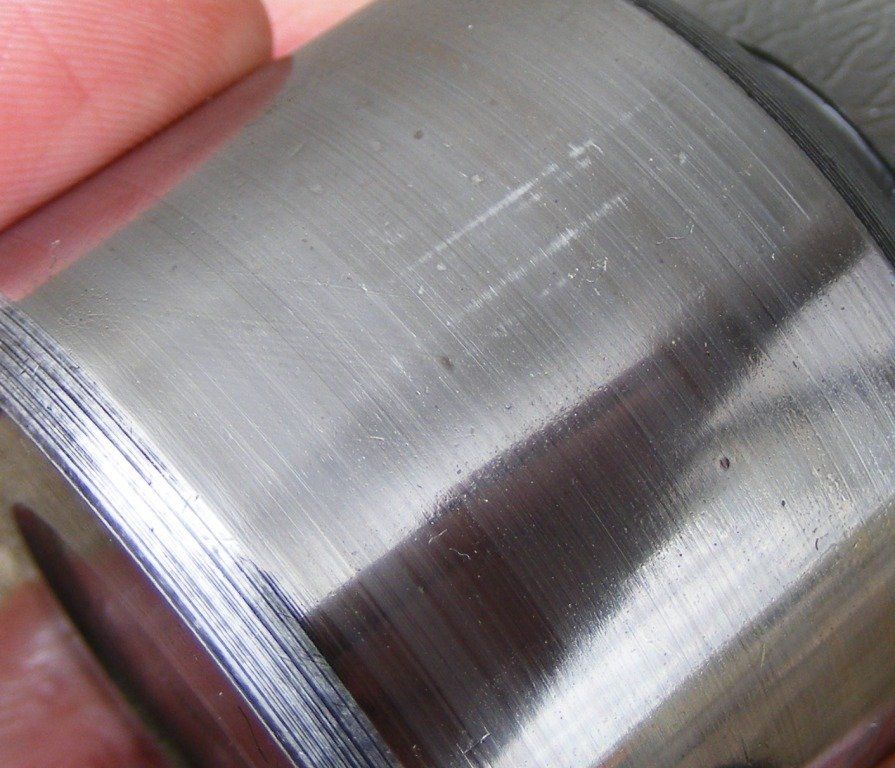

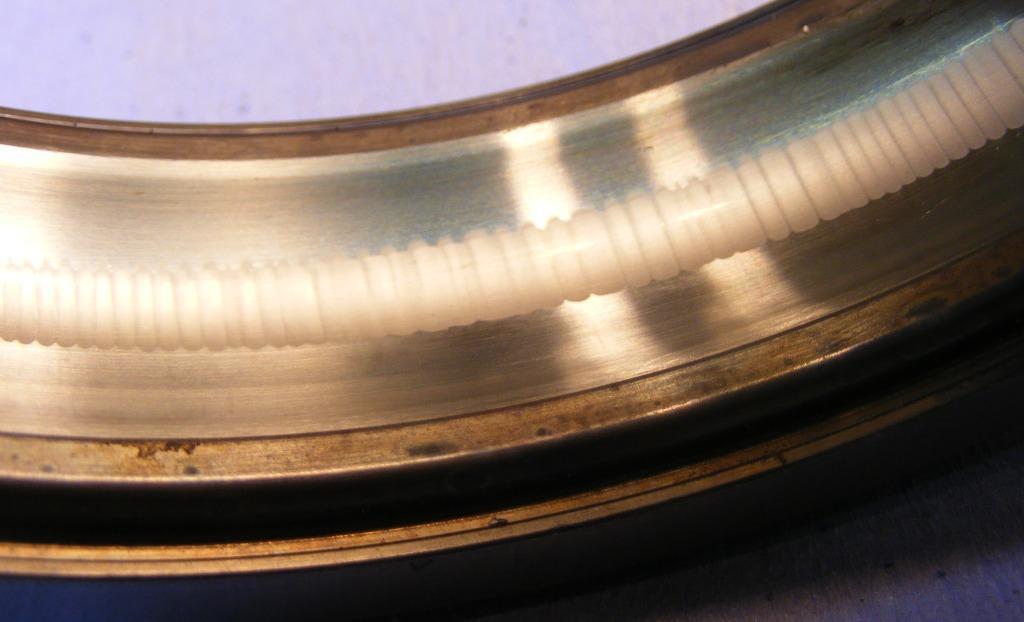

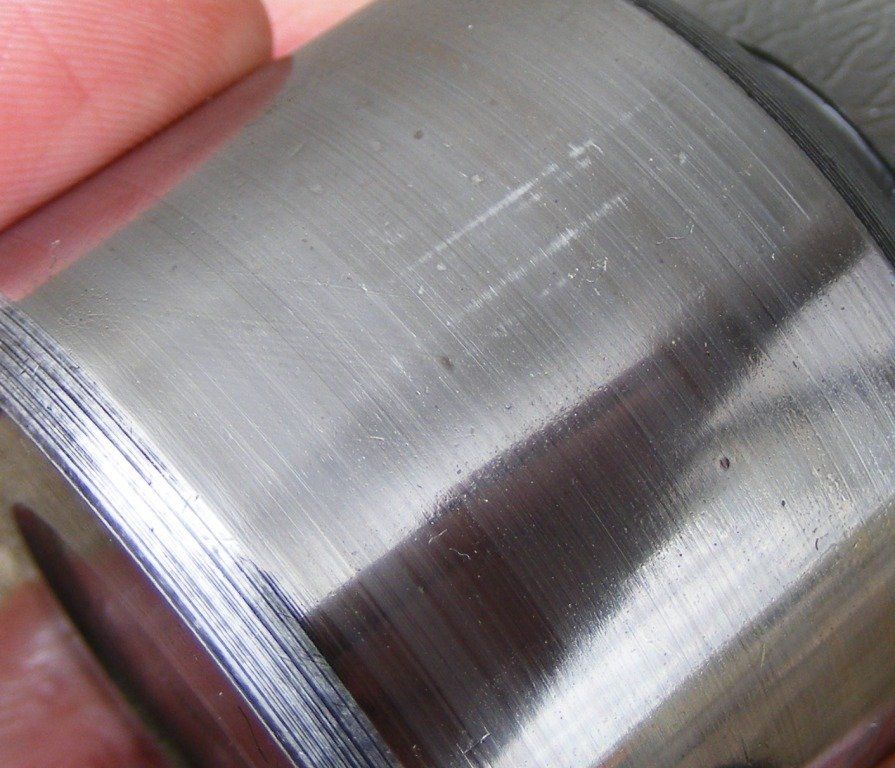

CREEP IN BEARINGS

Creep is the phenomenon in bearings where relative slippage occurs between fitting surfaces and thereby creates a clearance between the surfaces. Creep causes a shiny appearance, occasionally with scoring or wear.

Slide title

Inner ring bore creep due to a worn shaft

Button

-

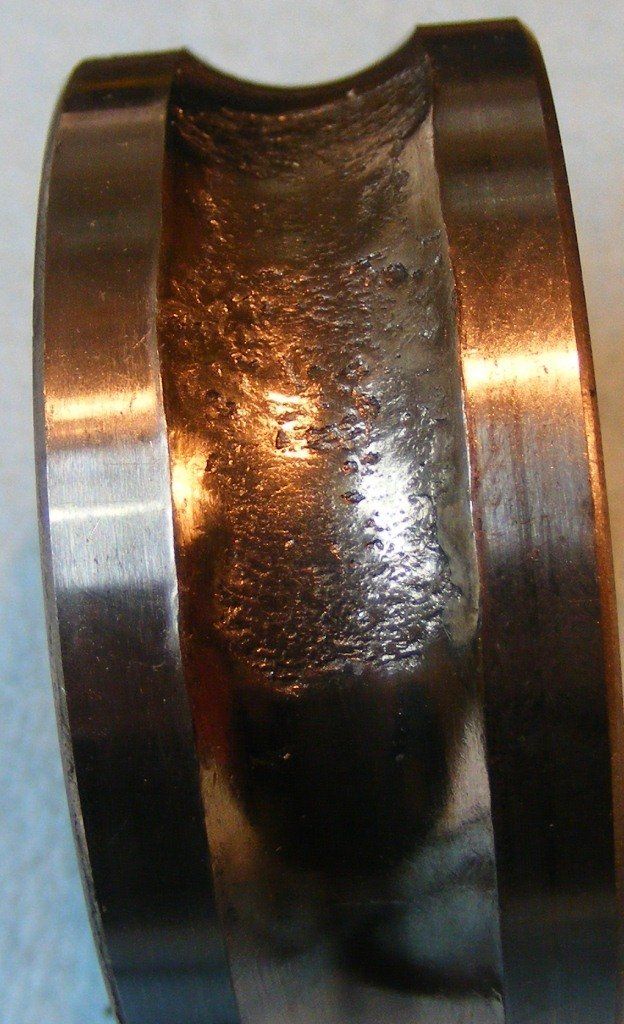

SEIZURE OF BEARINGS

When sudden overheating occurs during rotation, the bearing becomes discoloured. Then, the raceway rings, rolling elements, and cage will soften, melt and deform as damage accumulates.

Slide title

Tapered Roller Inner Rings distorted as a result of overloading and lack of lubrication

Button

Slide title

The remnants of rollers removed from a seized Taper Roller Bearing

Button

Slide title

Outer raceway from a seized tapered roller bearing

Button

Slide title

An angular contact bearing inner ring with material deposition from the balls following seizure

Button

Slide title

Tapered roller assembly with skewed and friction welded roller on one cone caused by assembly with an excess of end float

Button

-

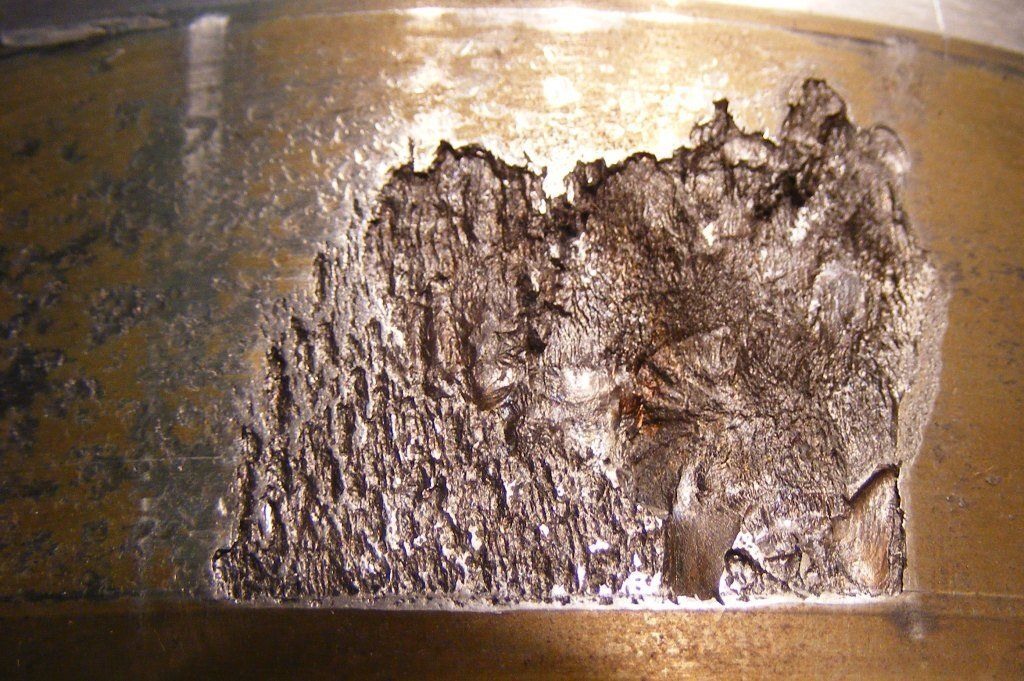

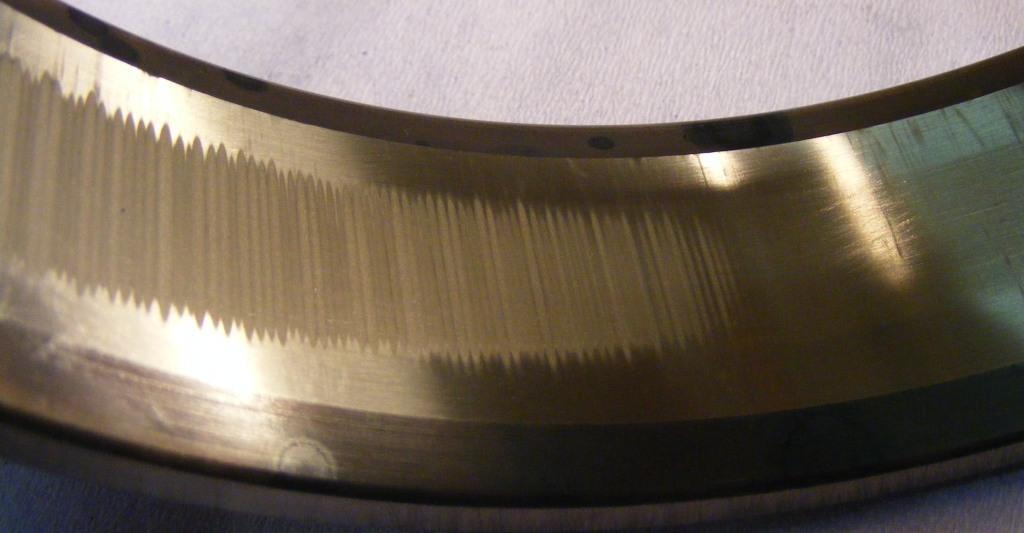

ELECTRICAL CORROSION IN BEARINGS

When electric current passes through a bearing, arcing and burning occur through the thin oil film at points of contact between the raceway and rolling elements. The points of contact are melted locally to form "fluting" or groove-like corrugations which can be seen by the naked eye. Magnification of these grooves reveals crater-like depressions which indicate melting by arcing.

Slide title

Electric arc pitting in a cylindrical roller outer ring

Button

Slide title

Electrical pitting in a spherical roller bearing

Button

Slide title

Electrical Pitting in a Spherical Roller bearing

Button

-

BEARING RUST AND CORROSION

Bearing rust and corrosion are pits on the surface of rings and rolling elements and may occur at the rolling element pitch on the rings or over the entire bearing surfaces.

Slide title

Inner ring side face rusting caused by a build-up of moisture in the bearing housing close to this deep groove ball bearing. Water ingress into the bearing has caused further cage and other internal surface corrosion to occur

Button

Slide title

Rust corrosion on a raceway caused by a bearing standing in moisture

Button

Slide title

Rusting of a ball bearing inner ring caused by moisture in the lubricant

Button

-

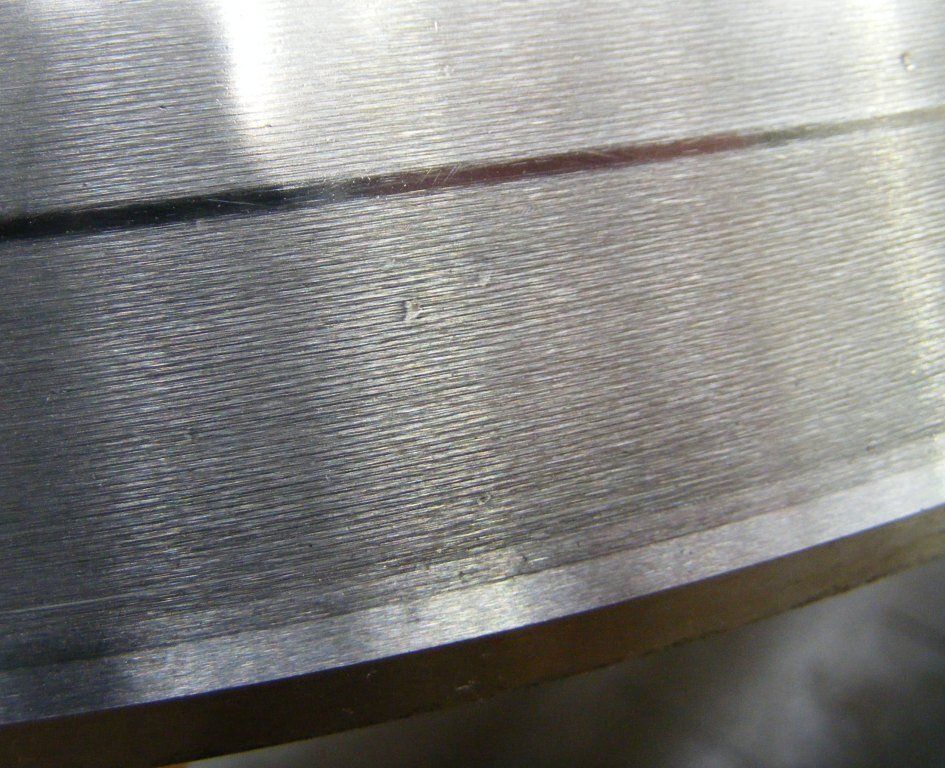

MOUNTING AND FITTING DAMAGE IN BEARINGS

Straight line scratches on surface of raceways or rolling elements caused during mounting or dismounting of bearing.

Slide title

Axial lines on the surface of a bearing roller caused by sliding during disassembly

Button

Slide title

Outer surface scratches caused during fitting. These marks are generally not detrimental to the bearing performance but do show that an interference fit was present between the bearing outer ring and the housing

Button

Slide title

Damaged outer surface of a double row Tapered Roller Bearing, Marks consistent with the ring having been loose in the application due to housing wear and dimensional inaccuracy. Discolouration to a deep blue caused by overheating at one side as a result of uneven loading

Button

Slide title

Line on a spherical roller outside diameter caused by a split housing design

Button

-

DISCOLOURATION OF BEARINGS

Discolouration of cages, rolling elements and raceway rings occurs due to their reacting with lubricant at high temperature or as a result of corrosion.

Slide title

Discolouration on a Tapered roller caused by lubricant deterioration

Button

Slide title

Discolouration on a Spherical roller caused by contaminated Lubricant.

Button

Slide title

Heat discolouration on a tapered roller inner ring.

Button

-

HOUSING OR SHAFT DAMAGE

Wear, corrosion and burrs caused by repeated replacement of new bearings, a contaminated or moist environment or heavy handling during bearing removal.

Slide title

A wheel hub with a damaged abutment shoulder, a worn and tapered housing bore and excessive corrosion due to the environment the bearings were used in

Button

Slide title

A vehicle stub shaft with wear caused by inner ring rotation and pick up

Button

-

BEARING FLAKING OR WEARING FATIGUE

Flaking due to rolling fatigue occurs when small pieces of bearing material are lifted and broken off the smooth surface of the raceway or the rolling elements. This flaking causes regions with a rough and coarse texture.

Slide title

Fatigue damage in a loaded zone of a

tapered roller bearing inner ring

Button

Slide title

Flaking on the edge of a tapered roller inner ring

Button

Slide title

A spherical roller damaged as a result of flaking and fatigue

Button

Slide title

Flaking on a ball bearing outer ring raceway

Button

Slide title

Flaking on a ball bearing outer ring raceway

Button

Slide title

Fatigue at both sides of a crack in a Tapered roller cone

Button

-

BEARING PEELING

Dull or cloudy spots appear on the raceway surface along with light wearing. Tiny microscopic cracks are generated downward from these cloudy spots to a depth of 5-10 μm. Small particles of material then peel from the surface with areas of minor flaking starting to occur.

Slide title

A spherical roller raceway with surface material peeled away

Button

-

BEARING SCORING

Scoring is surface damage due to accumulated small seizures caused by sliding under improper lubrication or severe operating conditions. Linear damage appears circumferentially on the raceway and roller surfaces. Cycloidal shaped damage on the roller ends and scoring on the rib surface contacting roller ends also occur.

Slide title

A spherical roller central divider scored as a result of an ineffective lubricant film thickness being present

Button

Slide title

A prominent scoring mark caused by a lack of radial clearance during service rotation. Swirl shaped scuffing and scoring on the ends of a failed taper roller bearing

Button

-

SMEARING OF THE BEARING SURFACE

Smearing is surface damage which occurs from a collection of small seizures between bearing components caused by oil film rupture and/or sliding. Surface roughening occurs along with melting.

Slide title

A smeared end of a tapered rolled as a result of excessive sliding contact against the roller retaining rib

Button

Slide title

Smearing on the inner races of a duplex tapered roller

Button

-

FRACTURE OF THE BEARING

Fracture refers to small or large metallic pieces which were broken off due to excessive load or shock load acting locally on a rolling element, rib or section of a raceway ring.

Slide title

Fracture of a spherical roller bearing outer ring as a result of a high thrust impact load causing cracks

Button

Slide title

Cracking in the outer ring of an angular contact bearing

Button

-

CRACKS IN THE RACEWAY RING AND ROLLING ELEMENTS

Cracks in the raceway ring and rolling elements. Continued use under this condition leads to larger cracks or fractures

Slide title

Outer ring crack caused by a heavy impact through the rolling elements

Button

Slide title

Inner ring crack caused by excessive hoop stress

Button

-

BEARING CAGE DAMAGE, DEFORMATION, FRACTURE AND WEAR

Cage damage includes: Cage deformation, Fracture and Wear Fracture of cage pillars.

Slide title

Tapered roller cage with worn side pillars caused by the bearing having run in a reduced lubricant condition

Button

Slide title

Wear in a brass cage pocket due to low lubrication

Button

Slide title

An angular contact bearing cage deformed due to rubbing contact with other assembly parts

Button

Slide title

Wear of pocket surface. Brass cage pillar wear caused by lack of lubrication

Button

-

SEIZURE OF BEARINGS

When sudden overheating occurs during rotation, the bearing becomes discoloured. Then, the raceway rings, rolling elements, and cage will soften, melt and deform as damage accumulates.

Slide title

Tapered Roller Inner Rings distorted as a result of overloading and lack of lubrication

Button

Slide title

The remnants of rollers removed from a seized Taper Roller Bearing

Button

Slide title

Outer raceway from a seized tapered roller bearing

Button

Slide title

An angular contact bearing inner ring with material deposition from the balls following seizure

Button

Slide title

Tapered roller assembly with skewed and friction welded roller on one cone caused by assembly with an excess of end float

Button

-

ELECTRICAL CORROSION IN BEARINGS

When electric current passes through a bearing, arcing and burning occur through the thin oil film at points of contact between the raceway and rolling elements. The points of contact are melted locally to form "fluting" or groove-like corrugations which can be seen by the naked eye. Magnification of these grooves reveals crater-like depressions which indicate melting by arcing.

Slide title

Electric arc pitting in a cylindrical roller outer ring

Button

Slide title

Electrical pitting in a spherical roller bearing

Button

Slide title

Electrical Pitting in a Spherical Roller bearing

Button

-

BEARING RUST AND CORROSION

Bearing rust and corrosion are pits on the surface of rings and rolling elements and may occur at the rolling element pitch on the rings or over the entire bearing surfaces.

Slide title

Inner ring side face rusting caused by a build-up of moisture in the bearing housing close to this deep groove ball bearing. Water ingress into the bearing has caused further cage and other internal surface corrosion to occur

Button

Slide title

Rust corrosion on a raceway caused by a bearing standing in moisture

Button

Slide title

Rusting of a ball bearing inner ring caused by moisture in the lubricant

Button

-

PITTING OF THE BEARING ON THE ROLLING ELEMENT OR RACEWAY

Pitting has a dull lustre and appears on the rolling element surface or raceway surface.

Slide title

Light pitting as seen on the two sides of a spherical roller inner ring

Button

Slide title

Pitting around the circumference of a cylindrical roller inner ring

Button

-

DENTING AND "PEAR SKINNING" OF THE BEARING

Flaking due to rolling fatigue occurs when small pieces of bearing material are lifted and broken off the smooth surface of the raceway or the rolling elements. This flaking causes regions with a rough and coarse texture.

Slide title

Dented cross roller thrust bearing raceway caused by dirt ingress following a strip down and re assembly

Button

Slide title

Raceway damaged by contaminant in the lubricant

Button

Slide title

Pear skinning caused by metal debris from a fatigue failure being pressed onto the remainder of the contact surface

Button

Slide title

Fatigue occurring on a ball bearing inner ring due to stresses induced around an impact dent

Button

-

WEAR OF BEARINGS

Wear is surface deterioration due to sliding friction at the surface of the raceway, rolling elements, roller end faces, rib face, cage pockets, etc.

Slide title

Rotation and surface wear in the bore of a tapered roller bearing inner ring. The possible cause being that the shaft was damaged previously allowing movement to occur

Button

Slide title

Close up of a Tapered Roller nose with heavy burrs and rotational scuffing due to maladjustment of the bearing on the shaft

Button

-

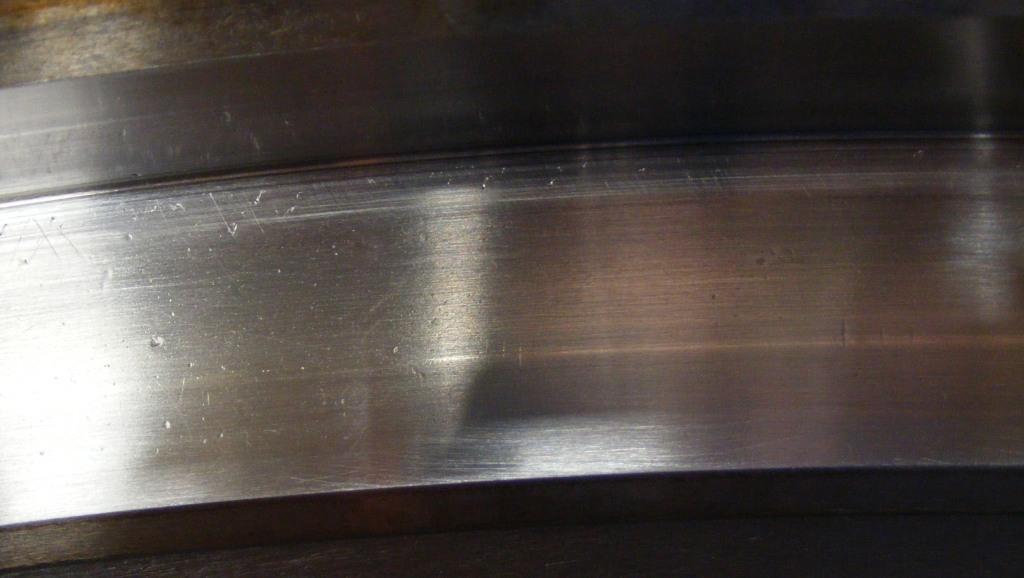

FRETTING OF BEARINGS

Wear occurs due to repeated sliding between the two surfaces. Fretting occurs at fitting surface between raceway rings and the shaft or housing. Fretting corrosion is another term used to describe the reddish brown or black wear patterns often seen on old shafts and worn housings.

Slide title

Top surface of a thrust bearing showing sliding wear marks to one side of the ring as a result of unintended movement during service

Button

Slide title

Fitting marks and fretting corrosion caused by the bearing vibrating on the shaft

Button

Slide title

Fretting Corrosion and Fitting marks on the outside diameter of a spherical roller outside diameter

Button

-

FALSE BRINELLING

Among the different types of fretting, false brinelling is the occurrence of hollow spots that resemble brinell dents and are due to wear caused by vibration and swaying at the contact points between the rolling elements and raceway.

Slide title

False brinelling caused during transportation of the stationary component

Button

Slide title

False brinelling and scratches likely to have been caused during transportation of inappropriately packed bearings

Button

-

CREEP IN BEARINGS

Creep is the phenomenon in bearings where relative slippage occurs between fitting surfaces and thereby creates a clearance between the surfaces. Creep causes a shiny appearance, occasionally with scoring or wear.

Slide title

Inner ring bore creep due to a worn shaft

Button

-

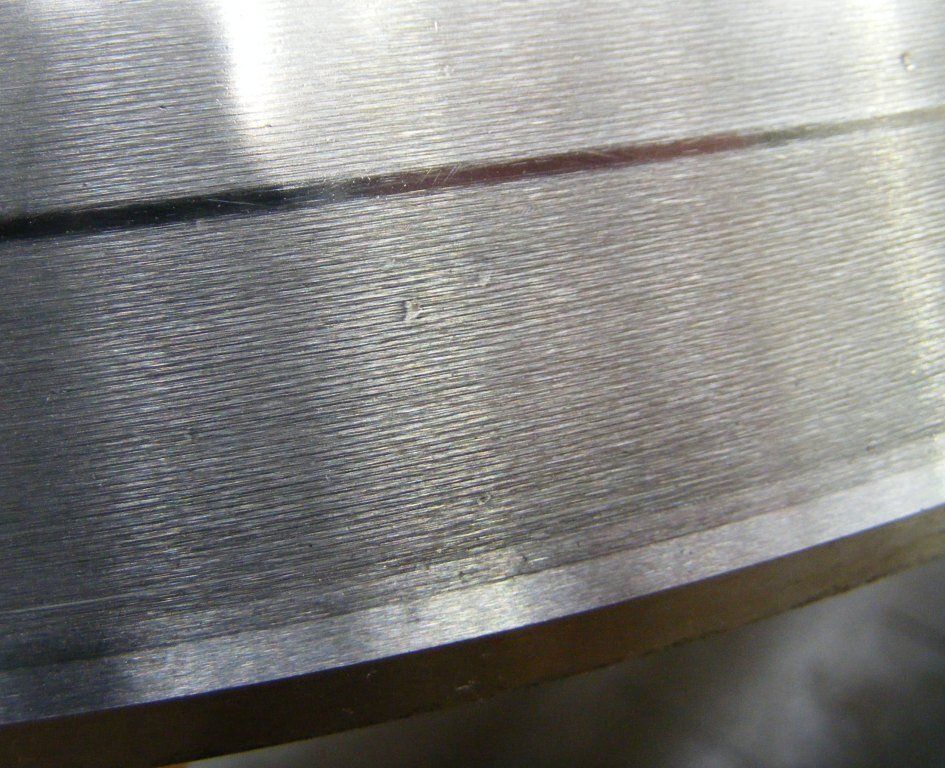

MOUNTING AND FITTING DAMAGE IN BEARINGS

Straight line scratches on surface of raceways or rolling elements caused during mounting or dismounting of bearing.

Slide title

Axial lines on the surface of a bearing roller caused by sliding during disassembly

Button

Slide title

Outer surface scratches caused during fitting. These marks are generally not detrimental to the bearing performance but do show that an interference fit was present between the bearing outer ring and the housing

Button

Slide title

Damaged outer surface of a double row Tapered Roller Bearing, Marks consistent with the ring having been loose in the application due to housing wear and dimensional inaccuracy. Discolouration to a deep blue caused by overheating at one side as a result of uneven loading

Button

Slide title

Line on a spherical roller outside diameter caused by a split housing design

Button

-

DISCOLORATION OF BEARINGS

Discoloration of cages, rolling elements and raceway rings occurs due to their reacting with lubricant at high temperature or as a result of corrosion.

Slide title

Axial lines on the surface of a bearing roller caused by sliding during disassembly

Button

Slide title

Outer surface scratches caused during fitting. These marks are generally not detrimental to the bearing performance but do show that an interference fit was present between the bearing outer ring and the housing

Button

Slide title

Damaged outer surface of a double row Tapered Roller Bearing, Marks consistent with the ring having been loose in the application due to housing wear and dimensional inaccuracy. Discolouration to a deep blue caused by overheating at one side as a result of uneven loading

Button

-

HOUSING OR SHAFT DAMAGE

Wear, corrosion and burrs caused by repeated replacement of new bearings, a contaminated or moist environment or heavy handling during bearing removal.

Slide title

A wheel hub with a damaged abutment shoulder, a worn and tapered housing bore and excessive corrosion due to the environment the bearings were used in

Button

Slide title

A vehicle stub shaft with wear caused by inner ring rotation and pick up

Button