Yes, regrettably, that is often the case. Many maintenance departments add grease to their rotating equipment on a regular basis and believe they are acting in the best interests of their machines. But grease is not a cure-all, at least without a little added ‘science.

Article by David Riley, Consultant Engineer JAD Associates

I recently spoke to the manager of an electrical motor repair and rewind company who recognised that adding too much grease often had unexpected side effects. He commented: ‘Many of the motors I rebuild proved end users did not always understand this fact’. He told me of a factory manager who suspected the bearings in one of his electric motors was starting to overheat. To overcome the problem, he added more grease to the housing until no more would go in. For about 10 minutes the temperature dropped but then the temperature started increasing again until the motor tripped. Faulty bearings were blamed, and the motor was sent for a rebuild.

AN EXTRA PUMP "FOR LUCK"

An investigation of the problem was undertaken by JAD Associates; this highlighted a motor manufacturer’s recommended grease interval of a few thousand hours running before a defined quantity of new grease should be added. The reality was that the motor was greased on a weekly basis using a grease gun that suppled the specified amount of new grease in just two strokes of the pump.

"When the maintenance technician was observed, he added three times the required quantity and often added an extra pump ‘for luck’. When it was explained that too much grease was causing the problems this was met with some scepticism."

When the maintenance technician was observed, he added three times the required quantity and often added an extra pump ‘for luck’. When it was explained that too much grease was causing the problems this was met with some scepticism.

YOU WILL END UP 'CHURNING'

Firstly “why does adding grease cause the bearing housing to cool then?” was asked. The reply was that the new grease had been taken from a cold storeroom and this cooler grease lowered the bulk temperature of the remaining lubricant until once again the grease got hot and tripped the motor.

When the motor was stripped, the bearing housings, and the void between the inner and outer raceways, was found to be completely full of compacted and hard grease. JAD was then able to explain that this excessive grease fill had not allowed cooling air to flow around the housing. This resulted in the grease in the housing getting hot due to an effect often referred to as ‘churning’ with no way for any heat generated to dissipate.

JUST HAVE A PADDLE

I was asked why, if the bearings were not faulty, was the motor drawing more power than usual and getting hot?

I explained the effect: When you are on a beach and feel like a walk, its often good to step into the water and just ‘have a paddle’. When, however, you try to walk up to your waist in the sea the effort needed is much greater and even in cold water you start to feel hotter and begin to use much more energy. This is what happens with the grease. The mechanical effort needed to rotate a fully packed bearing is greater than that required with a correctly packed and normal item. This mechanical effort generates heat, causing overheating and results in the grease degrading. The lubricant starts getting stiffer. That stiffness, in turn, causes more effort to be needed and eventually the system stops rotating.

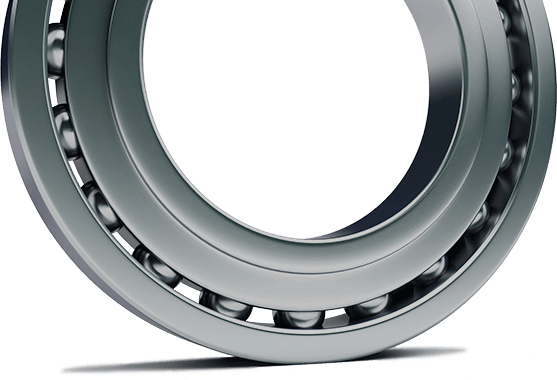

MOST "SEALED FOR LIFE" BEARINGS CONTAIN A GREASE FILL OF BETWEEN 25% TO 35%

The message is clear, confirm the manufacturer’s recommendation for re-lubricating and stick to it! Understand how much grease you are delivering and never add one more pump for ‘luck‘- your luck may just run out and cost a fortune to repair.

TALK TO US ABOUT YOUR BEARINGS ISSUES

Looking for expert help in understanding why your bearing failed and preventing problems in the future? JAD Analysis is independent from any one bearing manufacturer, so you can trust our experts to provide unbiased reports without prejudice. If you're interested in finding out what caused a bearing to fail or become damaged and possibly using our services, please call us on +44 (0)1673 843059 or use the contact form on this page to email your questions. You can upload a photograph of the bearing too either to gain a simple low cost rapid response or to help us quote for a more in depth piece of work.