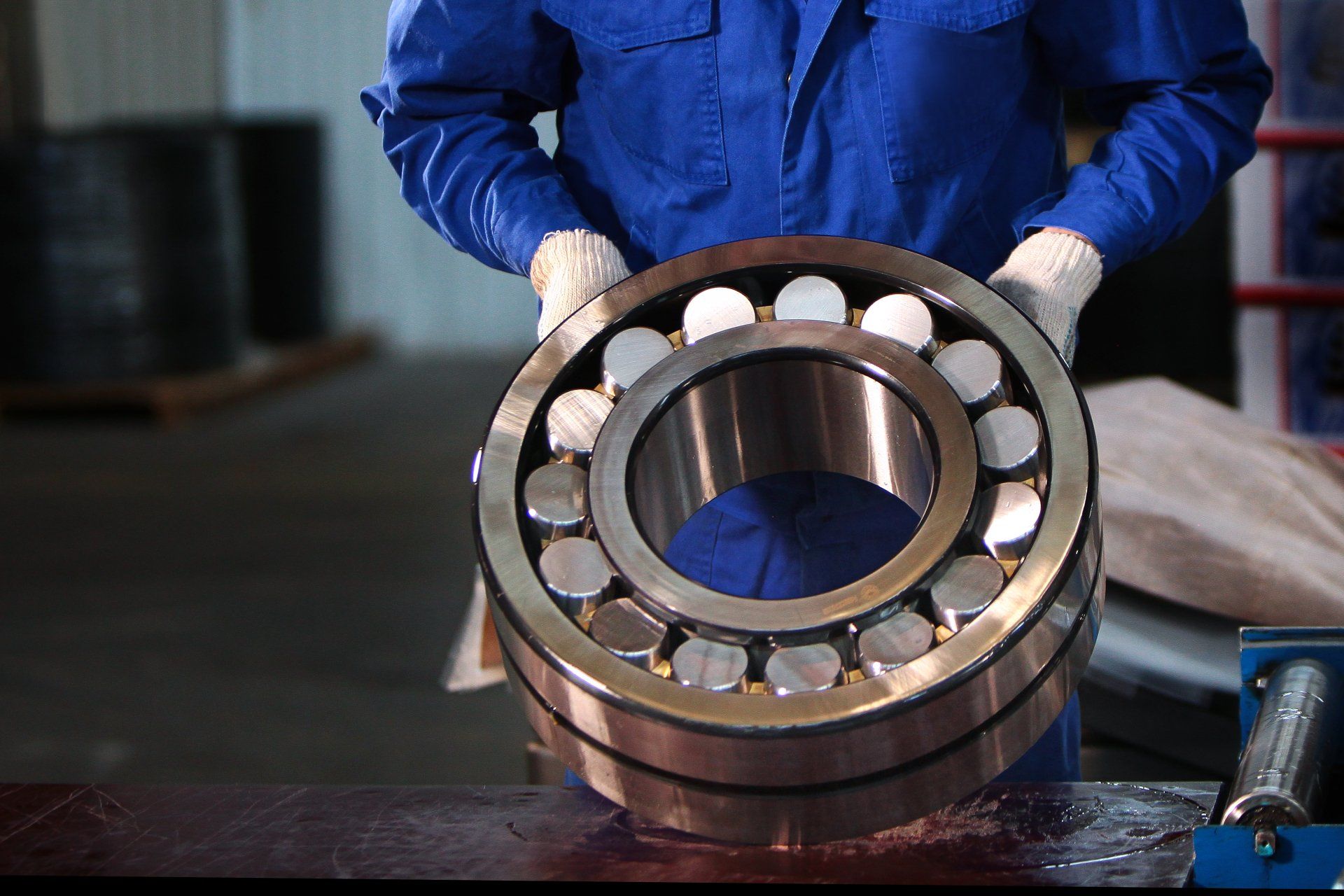

Rolling Element Bearings of all types and sizes are, like many other Engineering components, rapidly increasing in price due to the current global economic circumstances.

Article by David Riley, Consultant Engineer JAD Associates

In the first quarter of this year (2022) many large manufacturers had already increased prices by an average of 8%, it has been reported. The Russian-Ukrainian war also continues to affect the prices of raw materials and related components used in bearing manufacture. Available statistics are showing some critical raw materials increasing by over 100%, month on month. Natural Gas and electricity costs have also adversely affected bearing makers’ overheads, forcing prices up. As all makers are similarly affected, the cost of new bearings can only be heading one way, which is bad news for all bearing users.

Extending bearing life, incorporating maintenance, and reducing costs

Previously, many end users would treat all sizes of rolling element bearings as disposable items and simply change them in a failed machine, without thought. Economic considerations must surely start to change this way of thinking, with far more focus on route cause analysis to extend bearing life and make maintenance more cost effective. Throwing away an old and used bearing without checking its condition can often rob a machine user of valuable information on why bearing replacement was needed, and the also the condition of other machine parts.

"A recent investigation undertaken by ourselves highlighted that each time a set of bearings was changed, the accuracy of the shaft and housing was also affected"

Recently, we at JAD Analysis witnessed an end-user change bearings at increasingly regular intervals than was expected. The instinct was to blame the batch of bearings. Bearings from reputable manufacturers are extremely high precision items and have quality control checks in place all through the production process. Manufacturing defects in a batch of bearings is therefore highly unusual. A recent investigation undertaken by JAD highlighted that each time a set of bearings was changed, the accuracy of the shaft and housing was also affected. Metal was broached away from the shaft journals and housings, where interference fits were originally intended because of the removal process. In cleaning the journals and housings after bearing removal with an abrasive cloth or similar the size and shape of the shaft can be further affected. Marks on the outer surfaces of the bearing rings and on the load bearing contact marks will often show that this loss of fitting accuracy has occurred.

Many of the bearing failures we see can be avoided, thus reducing expenditure on new expensive parts but also eliminating the cost of process down time that can be crippling for an already stretched manufacturer.

Investigate your failed bearing to reduce costs in the future

Having a removed bearing inspected by an expert such as JAD Analysis (based in England, UK) who look for tell tail signs of impending problems, is one method forward-thinking organisations are employing to improve profitability and reduce costs. The cost of an 50mm bore bearing analysis, for example, is often less than the price of a full new set of replacement bearings.

Talk to us about your bearing issues

Looking for expert help in understanding why your bearing failed and preventing problems in the future? JAD Analysis is independent from any one bearing manufacturer, so you can trust our experts to provide unbiased reports without prejudice. If you're interested in finding out what caused a bearing to fail or become damaged and possibly using our services, please call us on +44 (0)1673 843059 or use the contact form on this page to email your questions. You can upload a photograph of the bearing too either to gain a simple low cost rapid response or to help us quote for a more in depth piece of work.